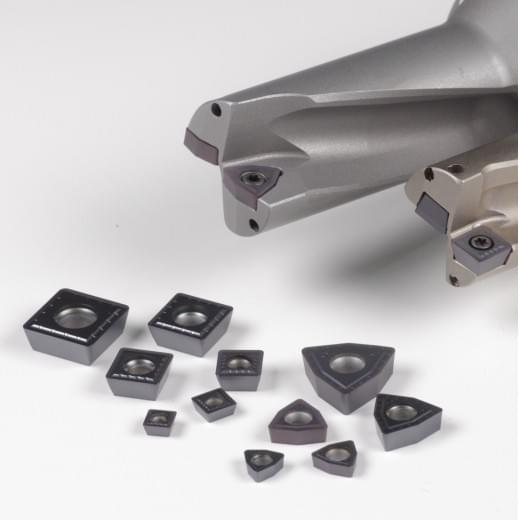

Main Products

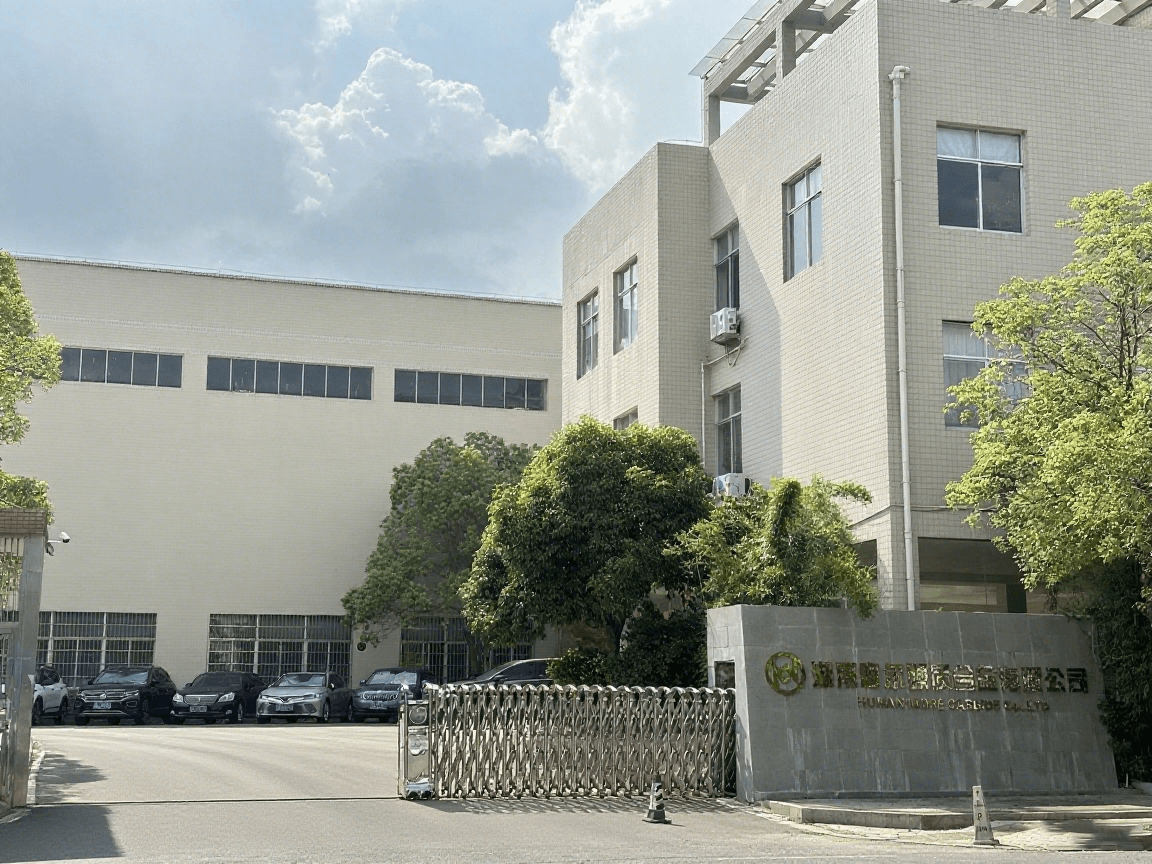

Hunan More Carbide Co., Ltd.

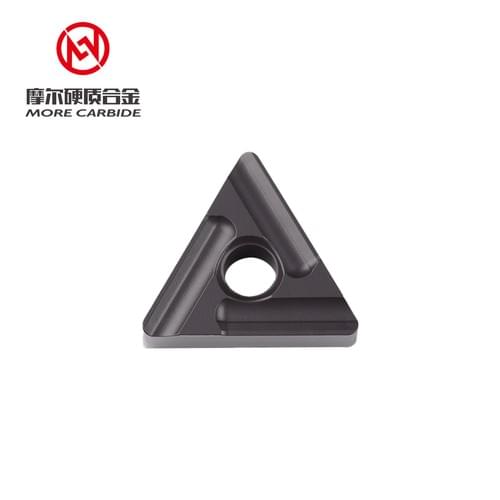

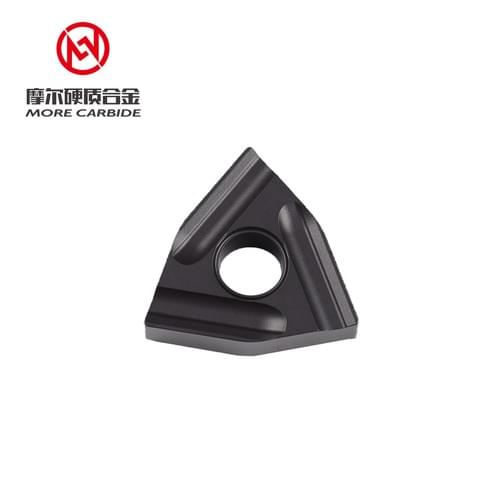

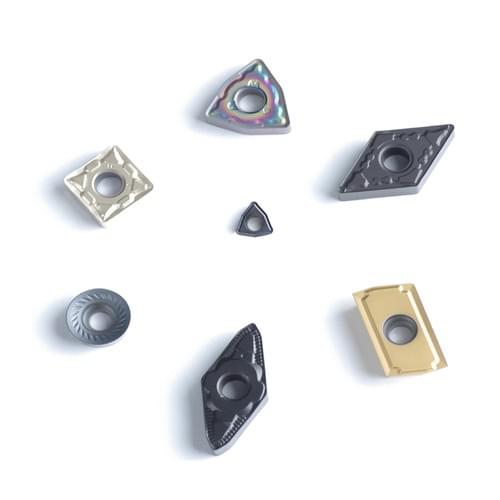

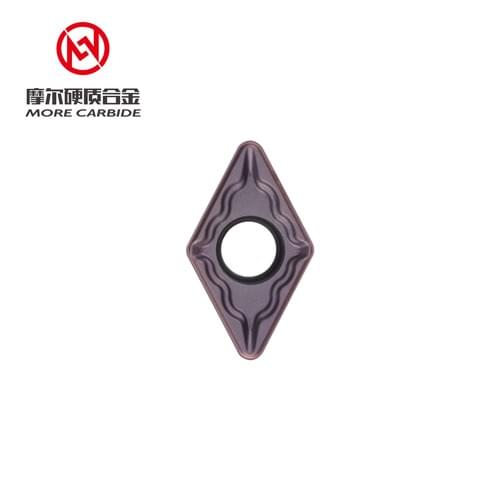

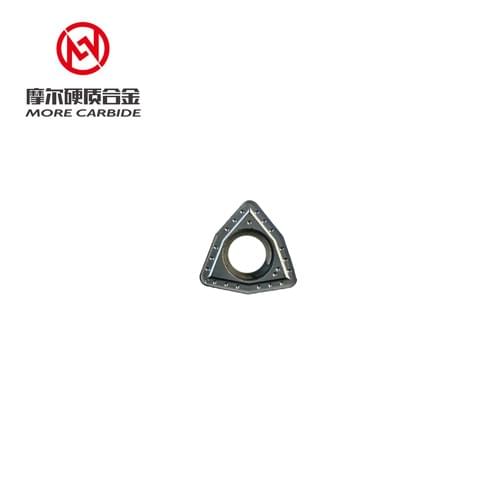

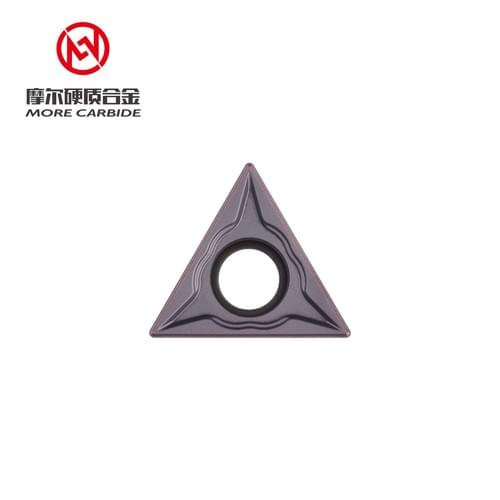

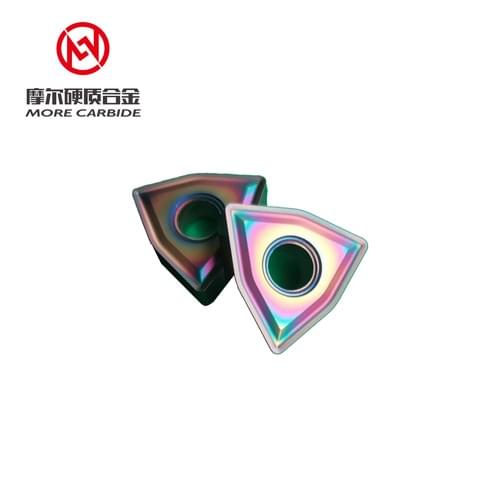

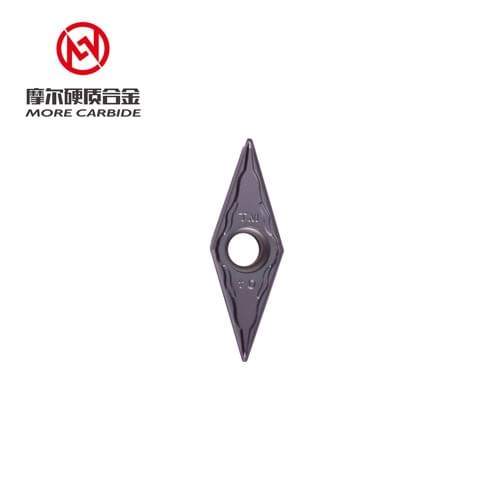

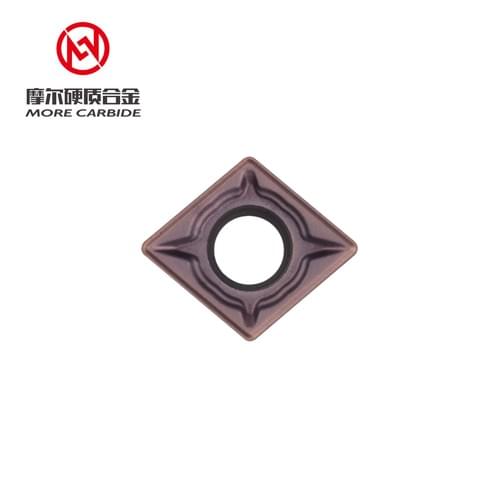

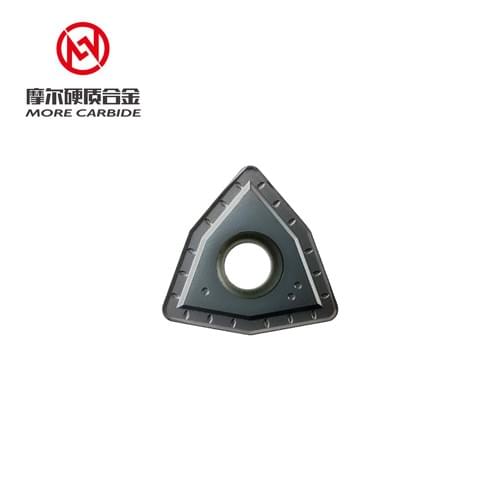

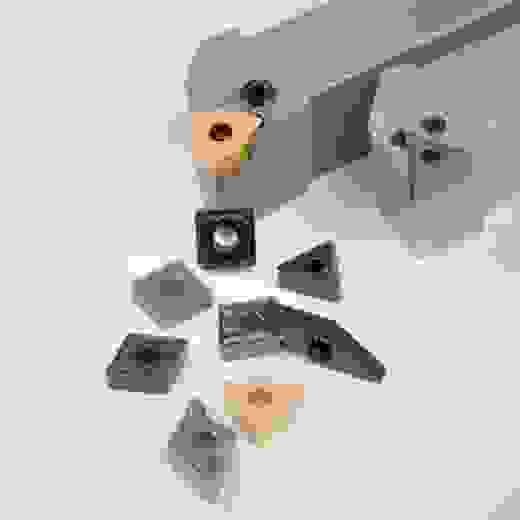

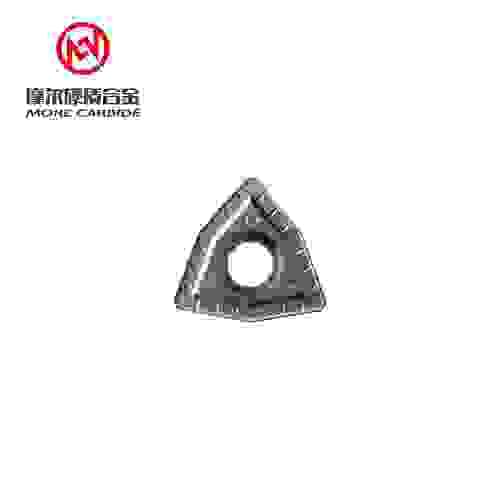

Turning Inserts

Turning inserts are used on CNC lathes for external turning, facing, boring, and threading. Common shapes include TNMG, CNMG, WNMG, DCMT, CCMT.

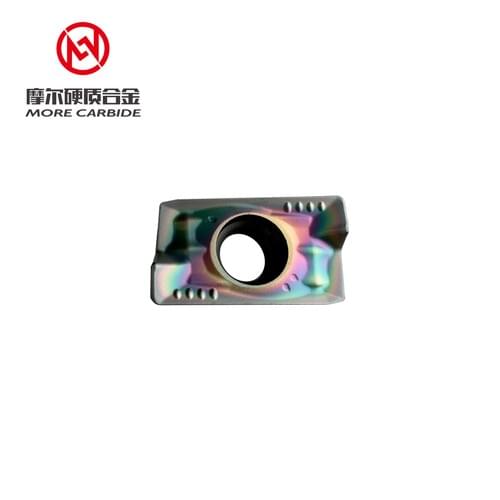

Milling Inserts

Milling inserts are mounted on indexable milling cutters for face milling, shoulder milling, and slotting. Common types: APMT, RPMT, RCKT.

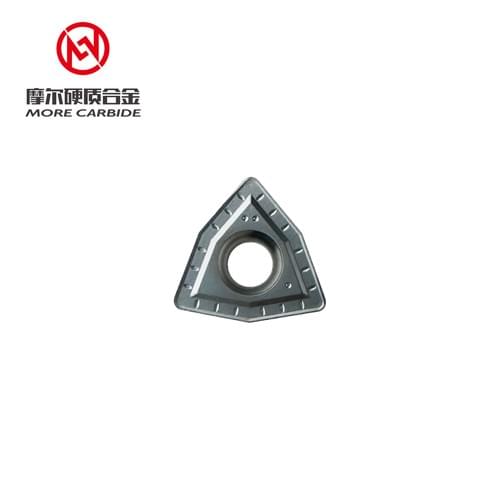

U-Drill Inserts

Indexable drill inserts are used in U drills and modular drilling tools for efficient hole making.

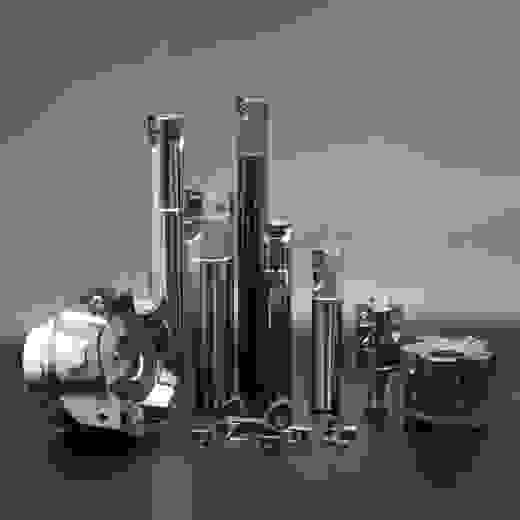

End Mills

Solid carbide end mills are monolithic tools for high-speed and precision milling.

Get to Know More Carbide in 1 Minutes

Reliable Supplier of Cemented Carbide Cutting Tools in China

- ● Fast Response

Quick support and communication to ensure smooth cooperation. - ● Customized Solutions

Tailored solutions to meet specific industry needs.

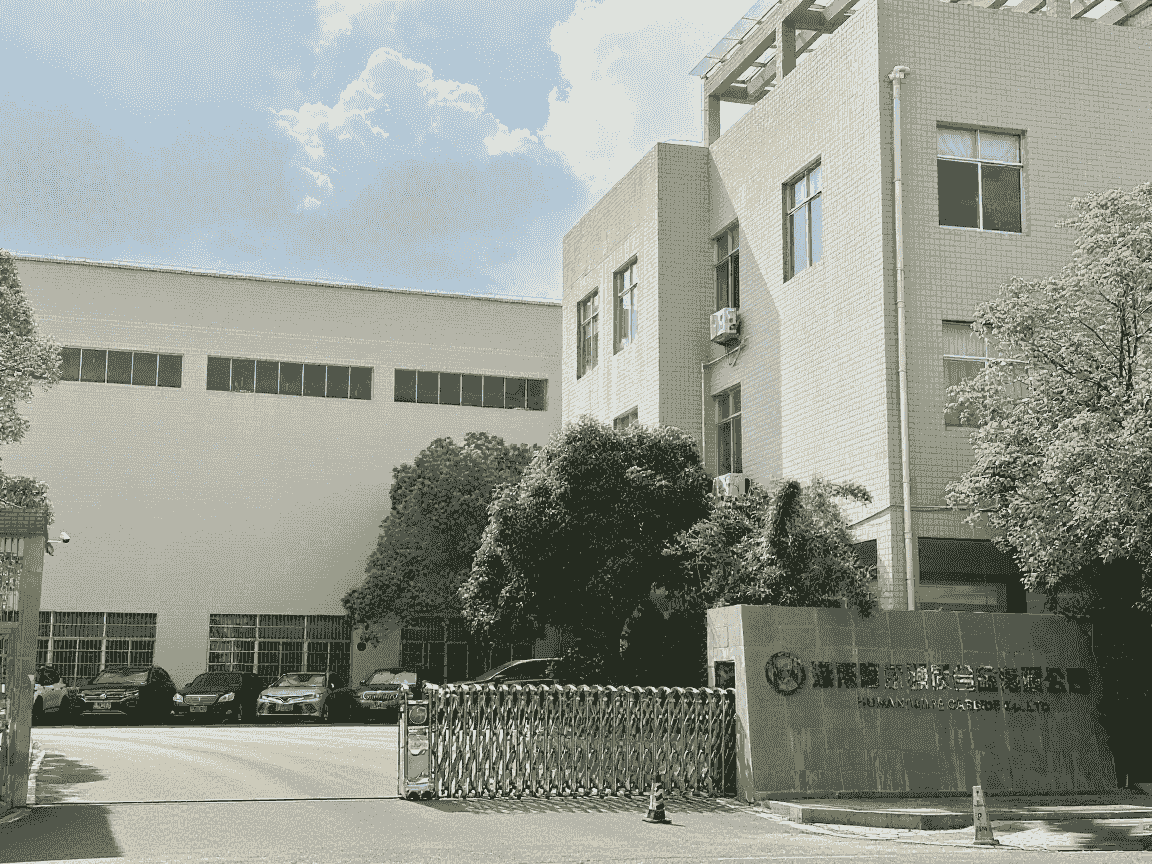

Hunan More Cemented Carbide Co., Ltd. is an innovative leader in the field of cemented carbide cutting tools.

We are a professional carbide cutting tools manufacturer based in Zhuzhou, Hunan, China.Founded in January 2017, our company integrates R&D, sales, and technical support of carbide cutting tools, and has been certified as a National High-Tech Enterprise in China.

- ● Fast Response

Core Advantages

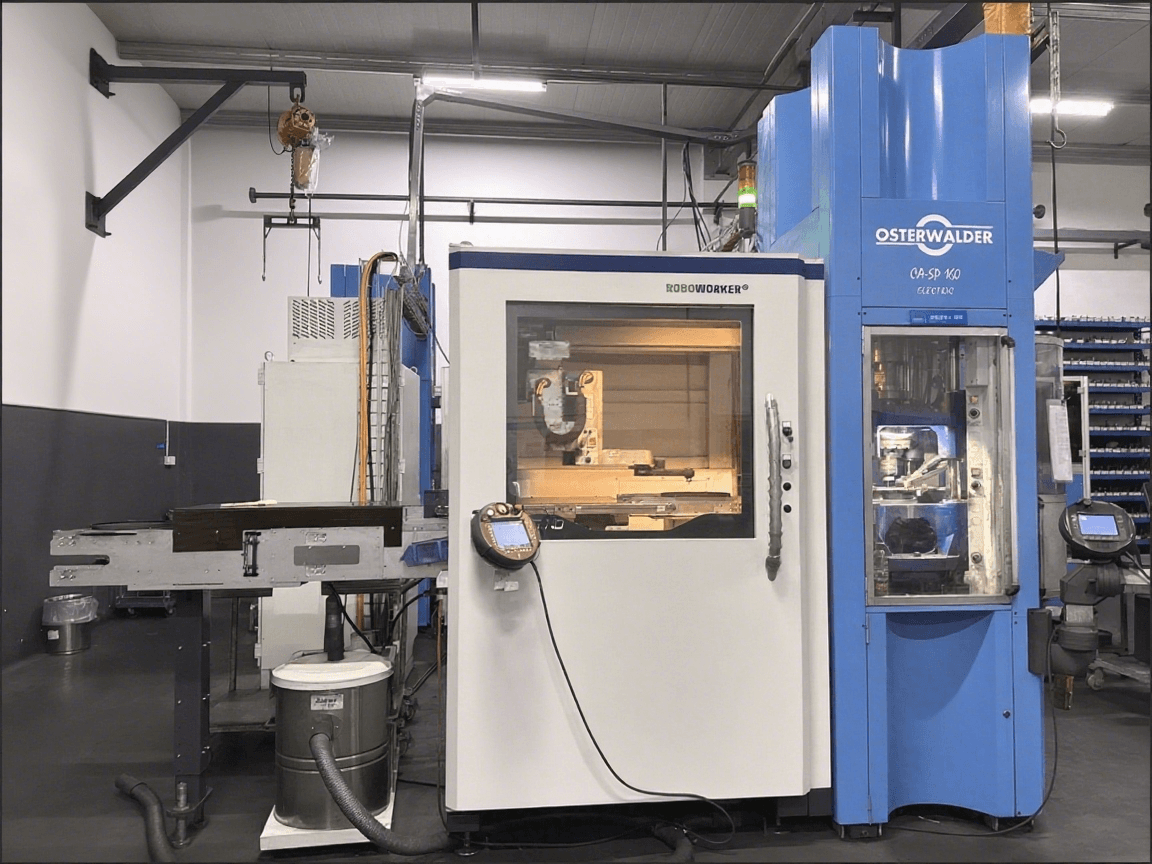

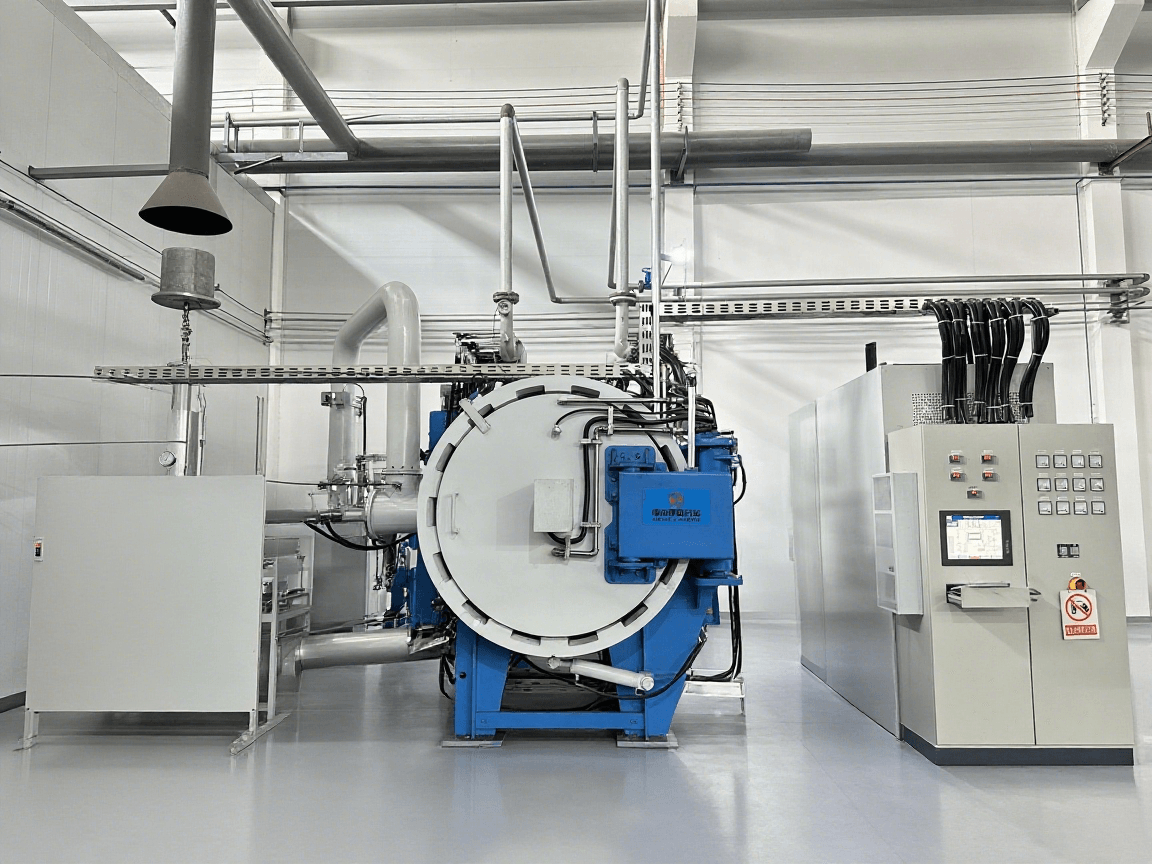

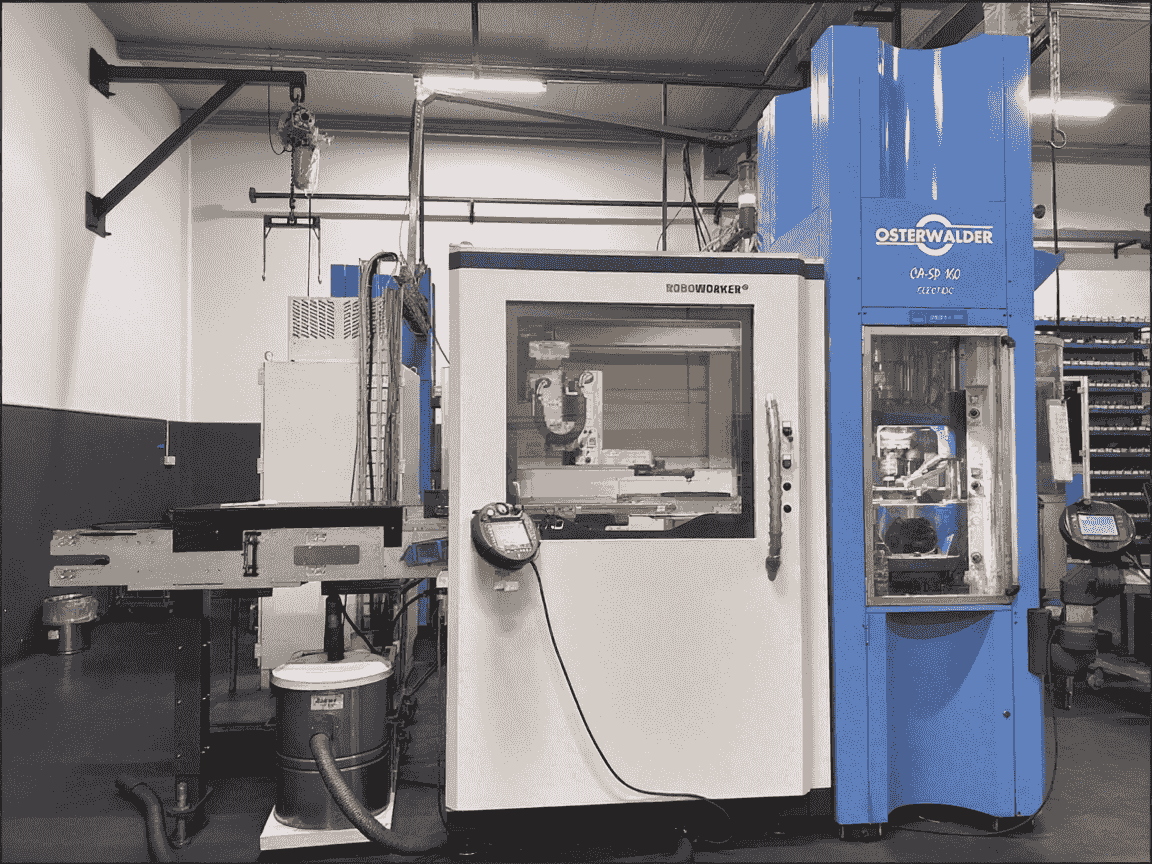

1Advanced Manufacturing System

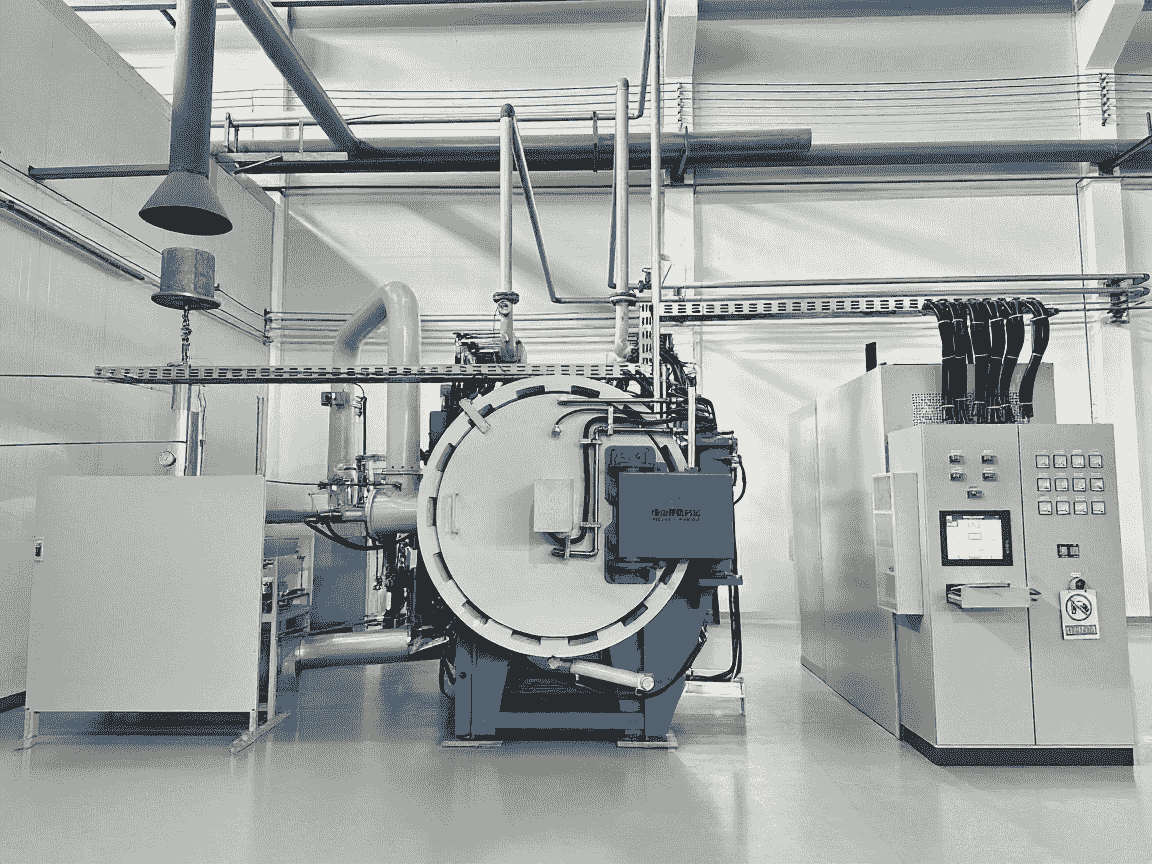

A modern production facility spanning over 10,000 square meters, equipped with a complete industrial chain: precision mold development → powder mixing → compacting → vacuum sintering → precision grinding → PVD/CVD coating → full-process quality control.

2Top-Tier Technical Team

Led by senior industry experts with decades of experience in materials science, tool design, coating technology, and machining applications.

3Precision Quality Assurance

Equipped with advanced inspection instruments such as metallographic laboratories and 3D measuring systems. Strict process control ensures stable performance of our products under demanding working conditions.

FACTORY LIVE SCENE

Administrative Building

Mold Processing

Alloy Preparation

Powder Compaction

Sintering Process

Coating Application

Why Choose Us?

Comprehensive Product Range for All Machining Needs

Our product line covers turning, milling, threading, parting, and grooving operations, suitable for both roughing and finishing of various materials like steel, stainless steel, and cast iron. Fully compatible with CNC machining centers and automatic line machines.

Proven Performance Across Multiple Industries

Our tools are widely used in industries such as automotive, aerospace, mold making, 3C electronics, and railway transportation, earning trust from global clients through proven performance.

Cost-Effective & Customizable for Your Unique Needs

Guided by our service philosophy of “prompt response and tailor-made solutions,” we support customized tool development to meet diverse machining scenarios. Our products rival top international brands in performance while offering far better value.

Featured Items

所有分类New productTurningMillingU-DrillSolid End MillingCUSTOMIZED SERIES WCMX06T308-UK U-Drill Insert|High-Efficiency Drilling with Stable Wear Resistance加载更多

WCMX06T308-UK U-Drill Insert|High-Efficiency Drilling with Stable Wear Resistance加载更多

Contact Us

📍 Address:

Tianxin High-Tech Park, Shifeng District

Zhuzhou City, Hunan Province, China

📧 Email:

info@

📞 Phone / WhatsApp:

+86 18173341603

Quick Inquiry

Welcome to visit our Alibaba International Store for more products and quotation details.